Important Product Categories of Sliding Resistors

I. Introduction

A. Definition of Sliding Resistors

Sliding resistors, also known as variable resistors, are electrical components that allow for the adjustment of resistance within a circuit. They are designed to provide a variable resistance that can be altered by moving a contact along a resistive element. This adjustability makes sliding resistors essential in various applications, from audio equipment to industrial controls.

B. Importance of Sliding Resistors in Electrical Engineering

In electrical engineering, sliding resistors play a crucial role in controlling current and voltage levels. They are integral to devices that require fine-tuning of electrical signals, enabling engineers and technicians to achieve desired performance levels. Their versatility and functionality make them indispensable in both consumer electronics and industrial applications.

C. Overview of the Article

This article will explore the important product categories of sliding resistors, including linear sliding resistors, rotary sliding resistors, potentiometers, rheostats, and digital sliding resistors. We will also discuss specialized types, factors to consider when choosing sliding resistors, and future trends in this technology.

II. Basic Principles of Sliding Resistors

A. How Sliding Resistors Work

1. Construction and Components

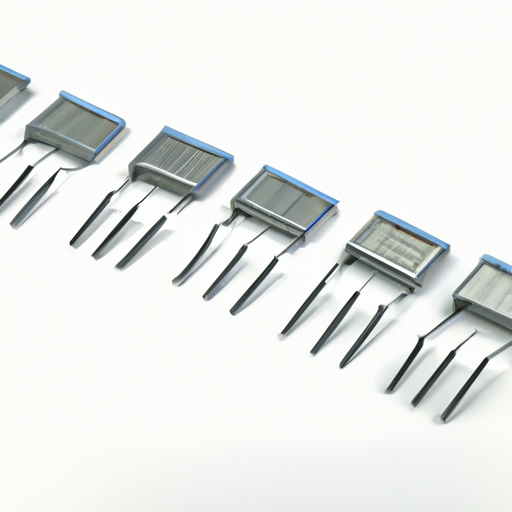

Sliding resistors typically consist of a resistive element, a sliding contact (or wiper), and terminals for electrical connections. The resistive element can be made from various materials, including carbon, metal film, or wire wound around an insulating core. The wiper moves along the resistive element, changing the resistance based on its position.

2. Mechanism of Resistance Variation

The resistance value is determined by the length of the resistive path between the wiper and the terminals. As the wiper moves, it alters the effective length of the resistive material, thus varying the resistance. This mechanism allows for smooth and continuous adjustment of resistance.

B. Applications of Sliding Resistors

1. Audio Equipment

In audio applications, sliding resistors are commonly used in volume controls and tone adjustments. They allow users to fine-tune sound levels and frequencies, enhancing the listening experience.

2. Industrial Controls

Sliding resistors are utilized in industrial settings for controlling motors, lights, and other equipment. They provide precise control over operational parameters, ensuring optimal performance and energy efficiency.

3. Laboratory Equipment

In laboratories, sliding resistors are employed in various instruments for calibration and measurement purposes. Their ability to provide variable resistance makes them ideal for experiments requiring precise electrical adjustments.

III. Key Product Categories of Sliding Resistors

A. Linear Sliding Resistors

1. Description and Features

Linear sliding resistors feature a straight resistive element and a wiper that moves linearly along its length. They are designed for applications requiring a direct relationship between the wiper position and resistance value.

2. Common Applications

These resistors are commonly found in audio equipment, dimmer switches, and other devices where linear control is essential.

3. Advantages and Disadvantages

**Advantages:** Linear sliding resistors provide smooth and predictable resistance changes, making them ideal for applications requiring precise control.

**Disadvantages:** They may have limited power ratings and can be less durable than other types, especially in harsh environments.

B. Rotary Sliding Resistors

1. Description and Features

Rotary sliding resistors, or rotary potentiometers, have a circular resistive element and a wiper that rotates around it. This design allows for compact integration into devices.

2. Common Applications

Rotary sliding resistors are widely used in volume controls, tuning knobs, and other applications where space is limited.

3. Advantages and Disadvantages

**Advantages:** They are compact and easy to integrate into various devices, providing a user-friendly interface.

**Disadvantages:** The rotational movement may not provide as fine control as linear options, depending on the application.

C. Potentiometers

1. Description and Features

Potentiometers are a type of sliding resistor that can be either linear or rotary. They consist of three terminals: two connected to the ends of the resistive element and one connected to the wiper.

2. Types of Potentiometers

a. Linear Potentiometers: These have a straight resistive path and are used in applications requiring linear adjustments.

b. Rotary Potentiometers: These have a circular resistive path and are commonly used in compact devices.

3. Common Applications

Potentiometers are used in audio equipment, control panels, and various electronic devices for adjusting voltage levels.

4. Advantages and Disadvantages

**Advantages:** Potentiometers offer versatility and can be used in a wide range of applications.

**Disadvantages:** They may wear out over time, leading to inconsistent performance.

D. Rheostats

1. Description and Features

Rheostats are a specific type of sliding resistor designed to handle higher power levels. They typically have two terminals and are used to control current in a circuit.

2. Common Applications

Rheostats are often used in applications such as motor speed control, lighting dimmers, and heating elements.

3. Advantages and Disadvantages

**Advantages:** Rheostats can handle high power loads and provide robust control over current.

**Disadvantages:** They can generate heat during operation, which may require additional cooling measures.

E. Digital Sliding Resistors

1. Description and Features

Digital sliding resistors, or digital potentiometers, use electronic components to achieve variable resistance. They can be controlled via digital signals, allowing for precise adjustments.

2. Common Applications

These resistors are commonly used in modern electronics, including audio devices, microcontrollers, and digital signal processing.

3. Advantages and Disadvantages

**Advantages:** Digital sliding resistors offer high precision and can be easily integrated into digital systems.

**Disadvantages:** They may be more expensive than traditional analog options and require additional circuitry for control.

IV. Specialized Sliding Resistors

A. Precision Sliding Resistors

1. Description and Features

Precision sliding resistors are designed for high accuracy and low tolerance levels. They are often used in applications requiring exact measurements.

2. Applications in Measurement and Calibration

These resistors are commonly found in laboratory equipment, testing devices, and calibration instruments.

B. High-Power Sliding Resistors

1. Description and Features

High-power sliding resistors are built to handle significant electrical loads without overheating. They are typically larger and more robust than standard sliding resistors.

2. Applications in Industrial Settings

These resistors are used in industrial applications such as motor control, power distribution, and heavy machinery.

C. Environmental and Ruggedized Sliding Resistors

1. Description and Features

Environmental sliding resistors are designed to withstand harsh conditions, including extreme temperatures, humidity, and vibration.

2. Applications in Harsh Conditions

They are commonly used in aerospace, automotive, and outdoor equipment where reliability is critical.

V. Factors to Consider When Choosing Sliding Resistors

A. Resistance Range

The resistance range required for the application is a primary consideration. Ensure the selected resistor can accommodate the necessary resistance values.

B. Power Rating

Consider the power rating to ensure the resistor can handle the expected load without overheating.

C. Linearity and Tolerance

Evaluate the linearity and tolerance specifications to ensure the resistor meets the precision requirements of the application.

D. Environmental Conditions

Consider the operating environment, including temperature, humidity, and exposure to contaminants, to select a suitable resistor.

E. Size and Form Factor

The physical size and form factor of the resistor should align with the design constraints of the device in which it will be used.

VI. Future Trends in Sliding Resistor Technology

A. Advances in Materials and Manufacturing

Innovations in materials and manufacturing processes are leading to more durable and efficient sliding resistors. These advancements may enhance performance and reduce costs.

B. Integration with Digital Technologies

As digital technologies continue to evolve, sliding resistors are increasingly being integrated into smart devices, allowing for enhanced control and automation.

C. Sustainability and Eco-Friendly Options

There is a growing emphasis on sustainability in electronics. Future sliding resistors may incorporate eco-friendly materials and manufacturing practices to reduce environmental impact.

VII. Conclusion

A. Recap of the Importance of Sliding Resistors

Sliding resistors are vital components in electrical engineering, providing essential functionality in a wide range of applications. Their ability to offer variable resistance makes them indispensable in both consumer and industrial electronics.

B. Summary of Key Product Categories

This article has explored various product categories of sliding resistors, including linear and rotary types, potentiometers, rheostats, and digital options. Each category has unique features, applications, advantages, and disadvantages.

C. Final Thoughts on the Future of Sliding Resistors in Technology

As technology continues to advance, sliding resistors will likely evolve to meet new demands and challenges. With ongoing innovations in materials, digital integration, and sustainability, the future of sliding resistors looks promising, ensuring their continued relevance in the ever-changing landscape of electrical engineering.

VIII. References

A. Academic Journals

- IEEE Transactions on Industrial Electronics

- Journal of Electrical Engineering & Technology

B. Industry Publications

- Electronic Design Magazine

- EDN Network

C. Manufacturer Specifications and Catalogs

- Vishay Intertechnology

- Bourns, Inc.