An Article to Help You Understand What a Thermistor Is

I. Introduction

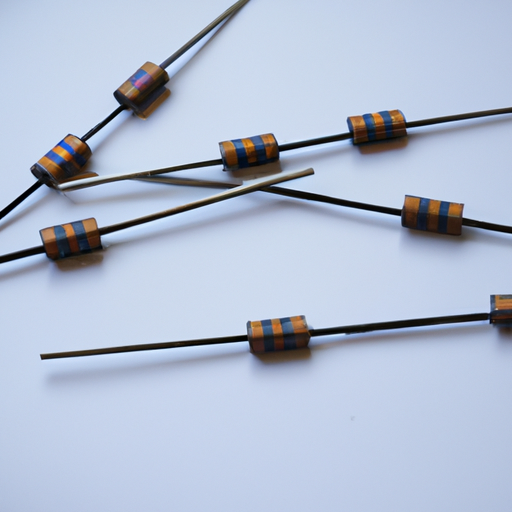

In the world of electronics and temperature sensing, thermistors play a crucial role. A thermistor, short for "thermal resistor," is a type of resistor whose resistance varies significantly with temperature. This unique property makes thermistors invaluable in a wide range of applications, from consumer electronics to industrial systems. The purpose of this article is to provide a comprehensive understanding of thermistors, including their history, functionality, types, applications, advantages, limitations, and future trends.

II. History of Thermistors

The journey of thermistors began in the early 20th century. The first thermistor was developed in the 1930s, when scientists discovered that certain semiconductor materials exhibited a change in resistance with temperature variations. This discovery laid the groundwork for the evolution of thermistor technology. Over the decades, advancements in materials science and manufacturing processes have led to the development of more sensitive and reliable thermistors.

Key milestones in thermistor research include the introduction of Negative Temperature Coefficient (NTC) thermistors in the 1950s, which became widely used due to their high sensitivity. The 1980s saw the emergence of Positive Temperature Coefficient (PTC) thermistors, which offered unique advantages in circuit protection applications. Today, thermistors are an integral part of modern technology, with ongoing research focused on enhancing their performance and expanding their applications.

III. How Thermistors Work

A. Basic Principles of Thermistor Operation

At the core of thermistor functionality is the relationship between resistance and temperature. As temperature increases, the resistance of NTC thermistors decreases, while PTC thermistors exhibit the opposite behavior—resistance increases with temperature. This characteristic allows thermistors to serve as precise temperature sensors.

B. The Role of Semiconductor Materials

Thermistors are typically made from semiconductor materials, such as metal oxides, which exhibit a significant change in resistance with temperature fluctuations. The choice of material affects the thermistor's sensitivity, response time, and temperature range.

C. Explanation of Temperature Coefficients

The temperature coefficient of a thermistor quantifies how much its resistance changes with temperature. For NTC thermistors, the temperature coefficient is negative, indicating that resistance decreases as temperature rises. Conversely, PTC thermistors have a positive temperature coefficient, meaning their resistance increases with temperature. Understanding these coefficients is essential for selecting the right thermistor for specific applications.

IV. Types of Thermistors

A. Negative Temperature Coefficient (NTC) Thermistors

NTC thermistors are characterized by their decreasing resistance with increasing temperature. They are widely used in temperature sensing applications due to their high sensitivity and accuracy. Common applications include temperature measurement in household appliances, automotive systems, and medical devices.

**Advantages:**

- High sensitivity to temperature changes

- Fast response time

- Cost-effective

**Disadvantages:**

- Limited temperature range

- Non-linear response characteristics

B. Positive Temperature Coefficient (PTC) Thermistors

PTC thermistors, on the other hand, increase in resistance as temperature rises. They are primarily used for overcurrent protection in circuits, as their resistance can limit current flow when temperatures exceed a certain threshold.

**Advantages:**

- Effective for circuit protection

- Simple to use in applications requiring current limiting

**Disadvantages:**

- Less sensitive than NTC thermistors

- Limited applications outside of protection circuits

C. Comparison Between NTC and PTC Thermistors

While both NTC and PTC thermistors serve important roles in temperature sensing and protection, their applications differ significantly. NTC thermistors are preferred for precise temperature measurements, while PTC thermistors excel in safety applications where current limiting is essential.

V. Applications of Thermistors

A. Consumer Electronics

In consumer electronics, thermistors are commonly used for temperature sensing in devices such as refrigerators, air conditioners, and ovens. They help maintain optimal operating conditions and enhance energy efficiency. Additionally, thermistors play a vital role in circuit protection, preventing overheating and potential damage to electronic components.

B. Automotive Industry

The automotive industry relies heavily on thermistors for engine temperature monitoring and climate control systems. NTC thermistors are used to measure coolant temperature, ensuring that engines operate within safe limits. PTC thermistors are employed in heating elements and as fuses to protect against overheating.

C. Medical Devices

In the medical field, thermistors are essential for patient monitoring systems, such as thermometers and heart rate monitors. They provide accurate temperature readings, which are critical for diagnosing and treating patients. Additionally, thermistors are used in laboratory equipment to maintain precise temperature conditions for experiments.

D. Industrial Applications

Thermistors are widely used in industrial applications, particularly in HVAC systems and process control. They help regulate temperature in heating and cooling systems, ensuring optimal performance and energy efficiency. In process control, thermistors monitor temperature in manufacturing processes, contributing to product quality and safety.

VI. Advantages of Using Thermistors

Thermistors offer several advantages that make them a popular choice for temperature sensing and control:

A. High Sensitivity and Accuracy

Thermistors are highly sensitive to temperature changes, providing accurate readings even with small fluctuations. This sensitivity is crucial in applications where precise temperature control is necessary.

B. Fast Response Time

Thermistors respond quickly to temperature changes, allowing for real-time monitoring and control. This rapid response is essential in applications such as automotive systems and medical devices.

C. Compact Size and Versatility

Thermistors are small and lightweight, making them easy to integrate into various devices and systems. Their versatility allows them to be used in a wide range of applications, from consumer electronics to industrial machinery.

D. Cost-Effectiveness Compared to Other Temperature Sensors

Compared to other temperature sensors, such as thermocouples and RTDs, thermistors are often more cost-effective. Their affordability, combined with their high performance, makes them an attractive option for many applications.

VII. Limitations of Thermistors

Despite their advantages, thermistors also have limitations that must be considered:

A. Temperature Range Limitations

Thermistors have a limited temperature range compared to other temperature sensors. NTC thermistors typically operate within -55°C to 125°C, while PTC thermistors have a narrower range. This limitation can restrict their use in extreme temperature environments.

B. Non-Linear Response Characteristics

The resistance-temperature relationship of thermistors is non-linear, which can complicate calibration and signal processing. This non-linearity may require additional circuitry or software to interpret the readings accurately.

C. Calibration Requirements

Thermistors often require calibration to ensure accurate temperature readings. This process can be time-consuming and may necessitate specialized equipment.

D. Environmental Factors Affecting Performance

Environmental factors, such as humidity and pressure, can impact the performance of thermistors. These factors must be considered when selecting and deploying thermistors in various applications.

VIII. Future Trends in Thermistor Technology

As technology continues to advance, the future of thermistor technology looks promising. Key trends include:

A. Advances in Materials and Manufacturing

Research is ongoing to develop new materials that enhance the performance of thermistors. Innovations in manufacturing processes may lead to more reliable and sensitive thermistors, expanding their applications.

B. Integration with Smart Technology and IoT

The rise of smart technology and the Internet of Things (IoT) presents new opportunities for thermistors. Integration with smart devices can enable real-time monitoring and control, enhancing energy efficiency and user experience.

C. Potential for New Applications in Emerging Fields

As industries evolve, thermistors may find new applications in emerging fields such as renewable energy, smart homes, and wearable technology. Their versatility and performance make them well-suited for these innovative applications.

IX. Conclusion

In summary, thermistors are essential components in modern technology, offering high sensitivity, fast response times, and cost-effectiveness. Their applications span various industries, from consumer electronics to medical devices and industrial systems. While they have limitations, ongoing research and advancements in technology promise to enhance their performance and expand their use in the future. Understanding thermistors is crucial for anyone interested in temperature sensing and control, and further exploration of this fascinating technology is encouraged.

X. References

1. "Thermistors: Principles and Applications" - Journal of Electronic Materials

2. "Temperature Sensors: A Comprehensive Guide" - Electronics Tutorials

3. "Advancements in Thermistor Technology" - IEEE Transactions on Industrial Electronics

4. "Thermistors in Medical Devices" - Medical Device Technology Journal

5. "The Future of Temperature Sensing" - Sensors Magazine

This article provides a thorough overview of thermistors, their functionality, and their significance in various applications. By understanding thermistors, readers can appreciate their role in the ever-evolving landscape of technology.